Select a file to view it.

Update 10/03/22: Adding a few alternative STLs.

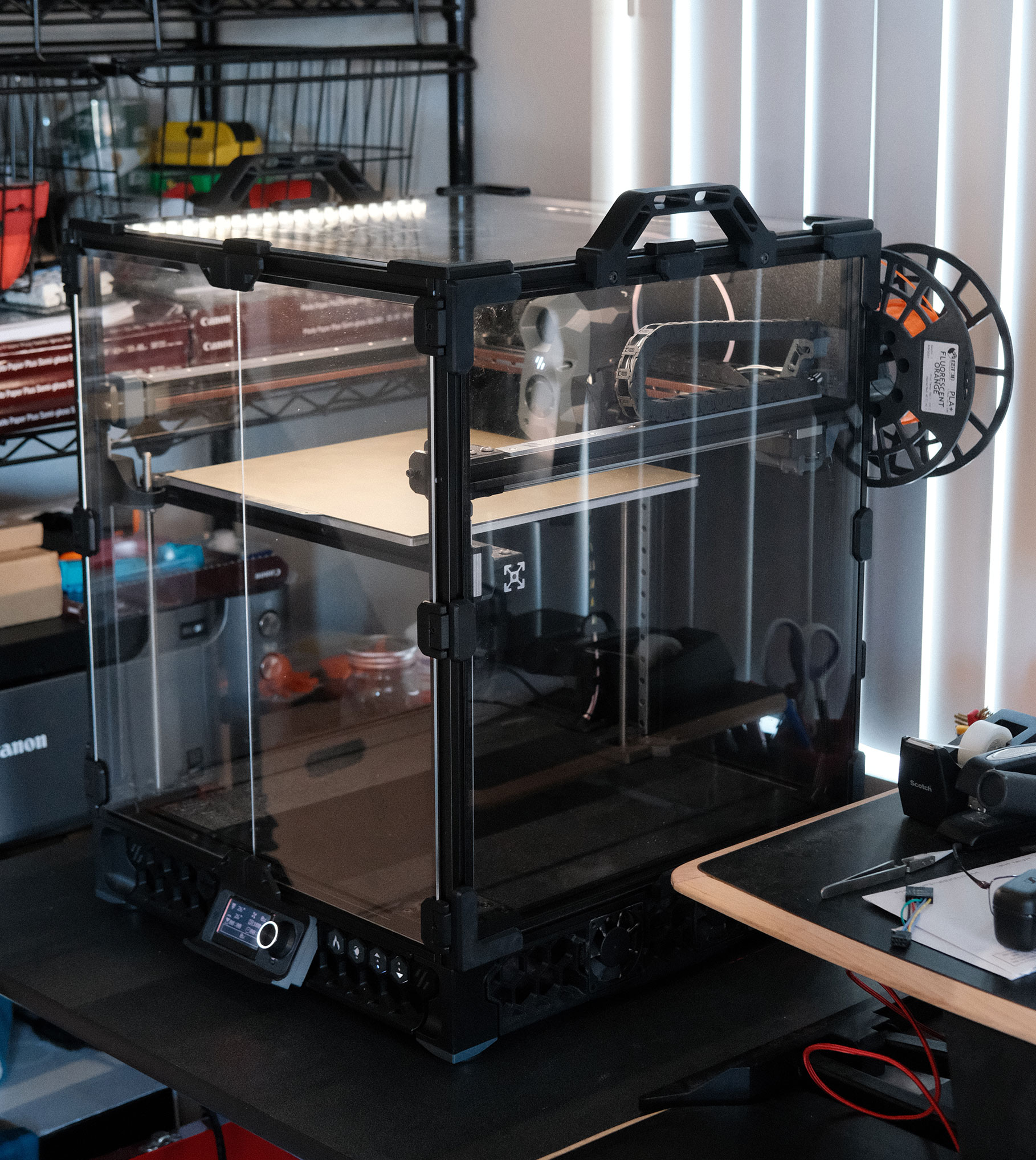

There are various panel latches and magnetic clips that offer quick panel removal for swapping between enclosed- and open-chamber printing, but I wanted to fix a few of the pain points that I ran into with some of the existing mods.

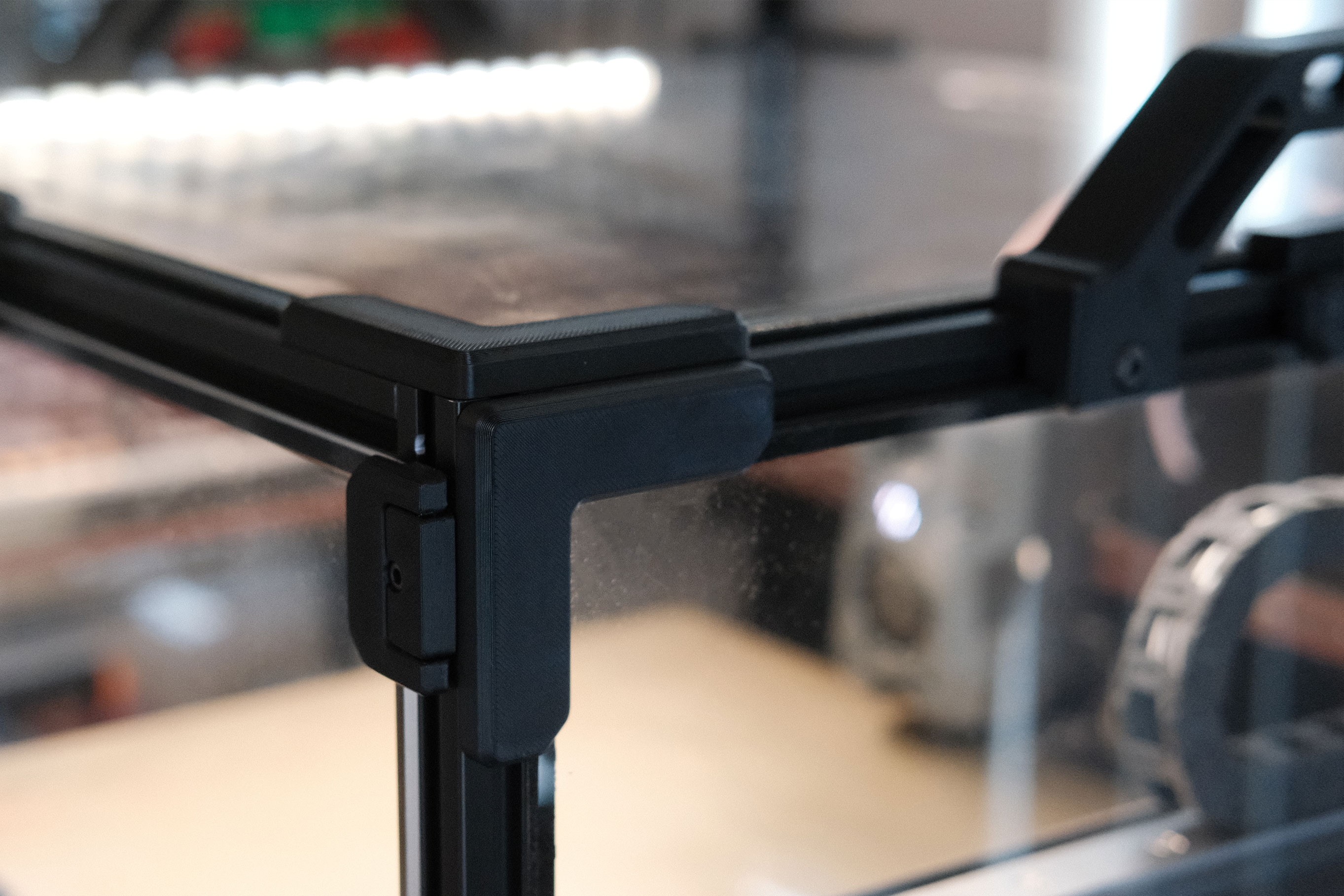

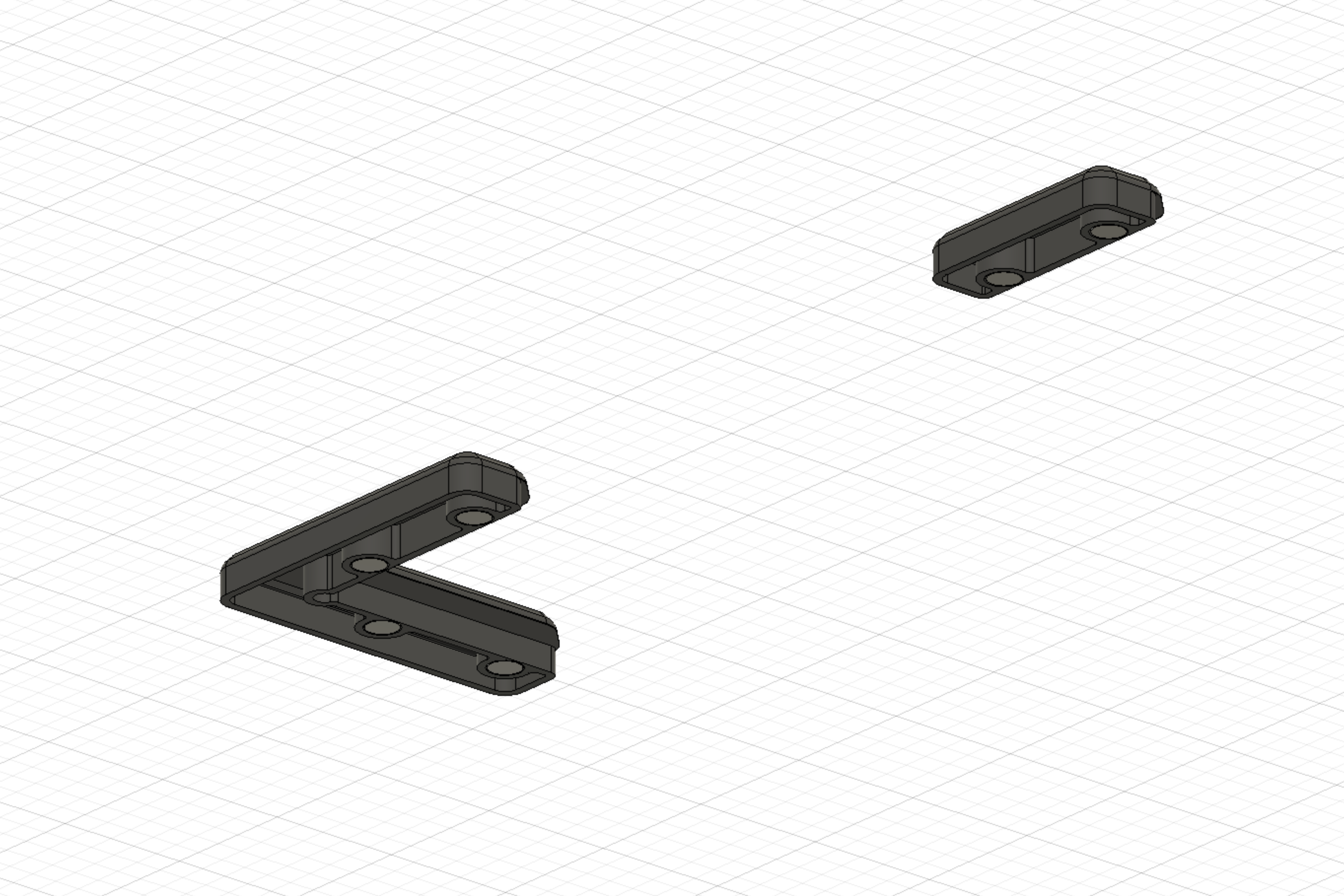

Does not require a lot of filament. The corner and mid-panel clips were modeled after the stock Trident panel clips and are similarly hollowed, saving filament and print time.

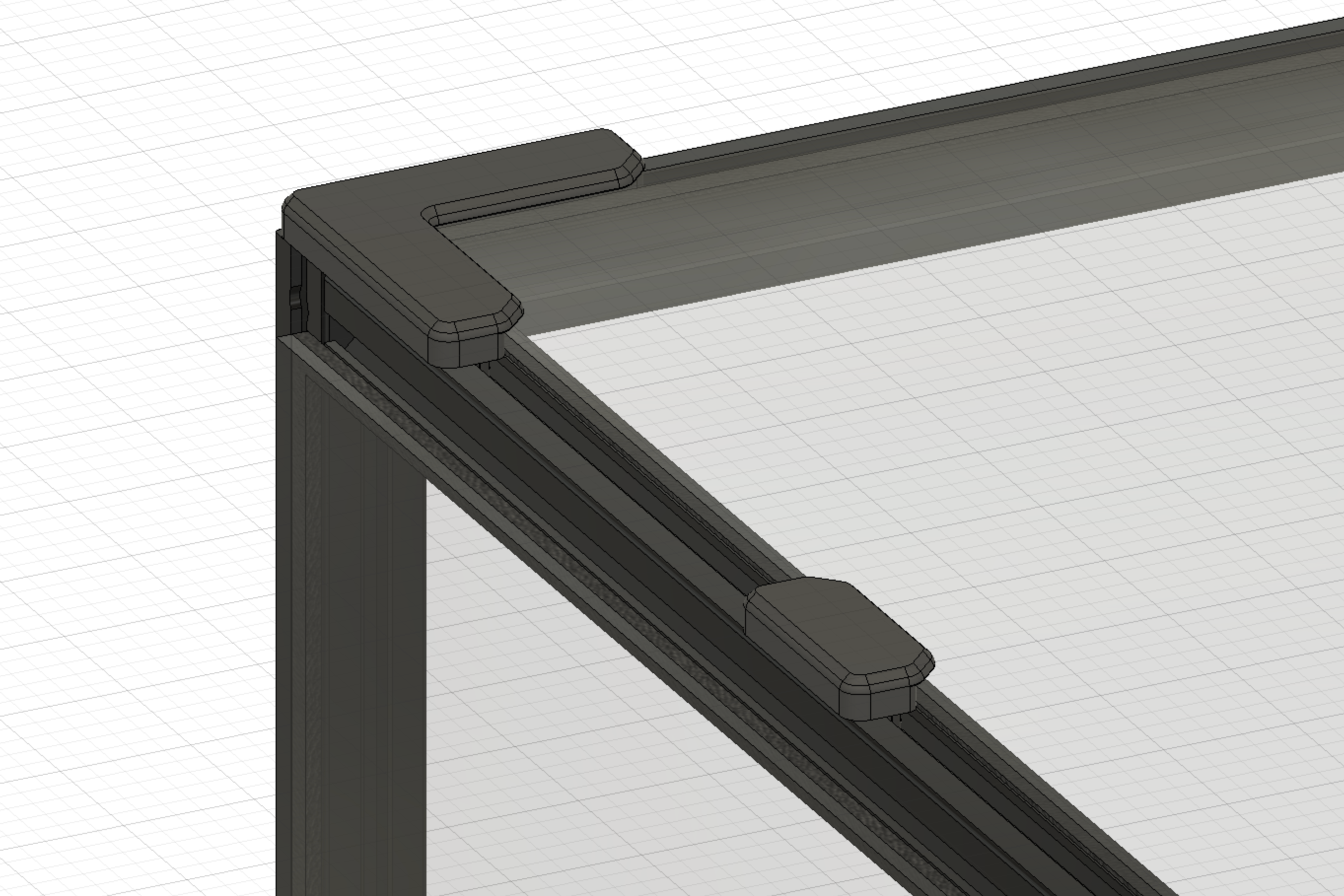

Uses a thin strip of VHB to adhere to the panels. This should provide (1) solid adhesion without the need for drilling or extra fasteners, (2) some amount of squish for the magnets to pull against, and (3) the ability to adjust or remove them in the future.

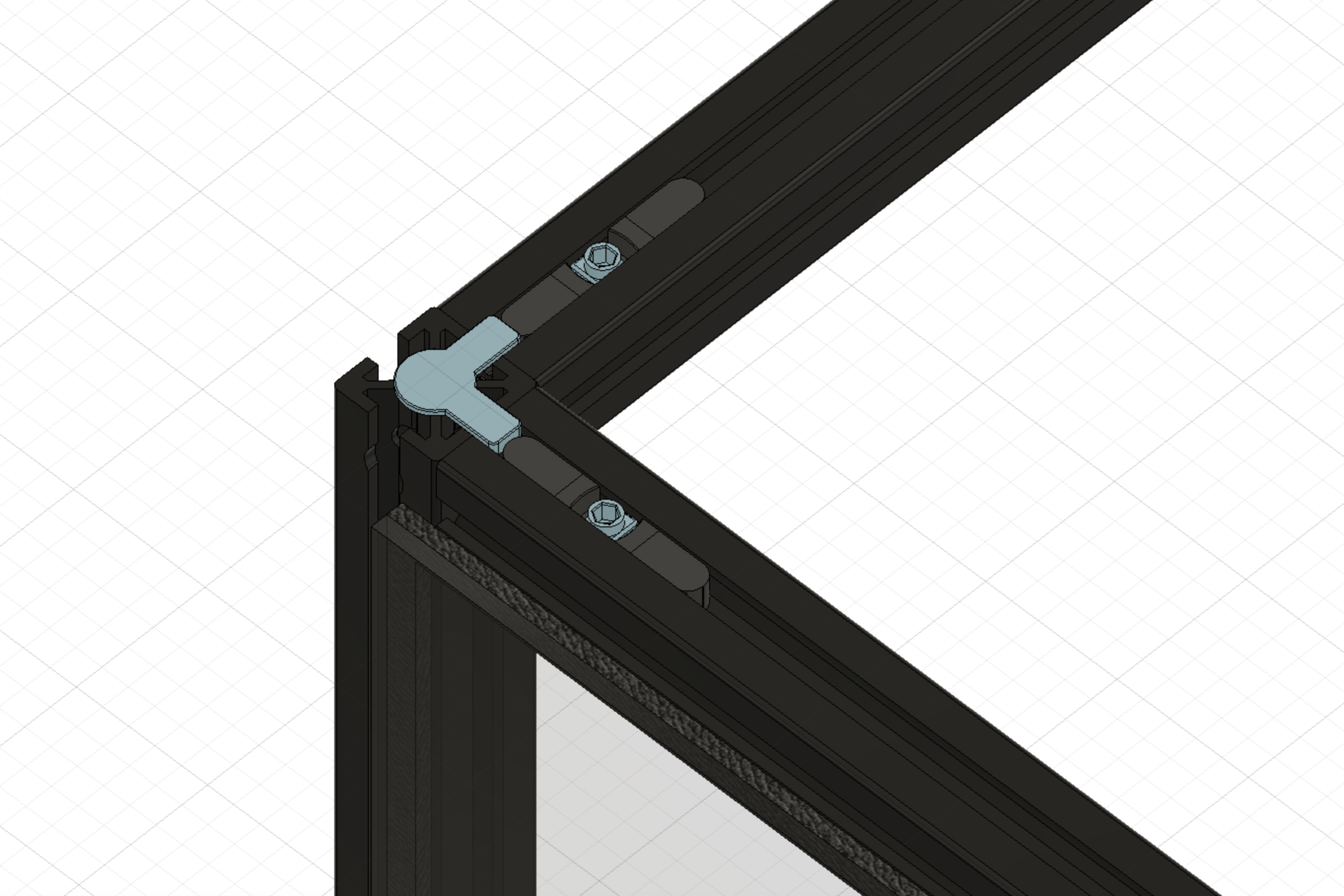

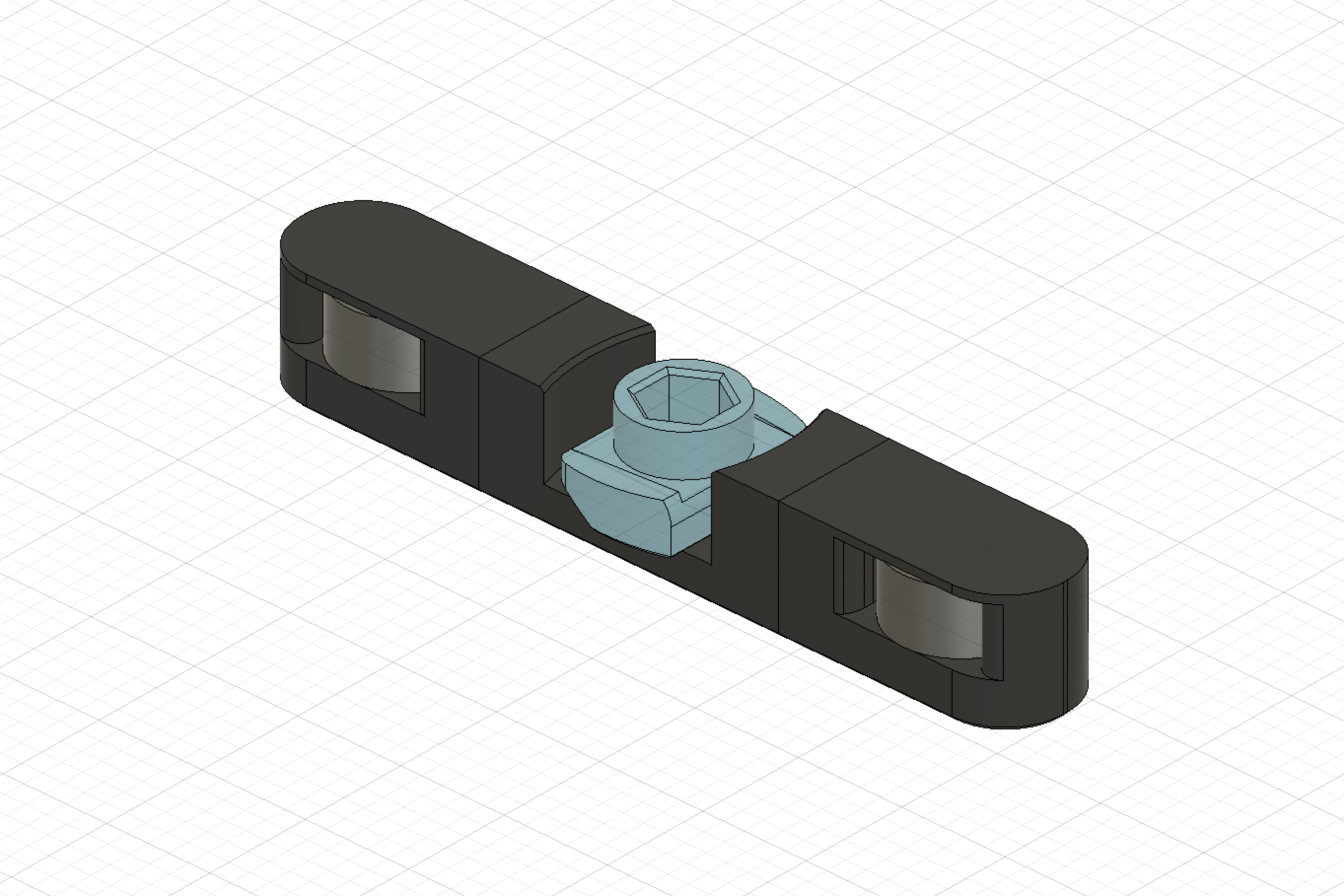

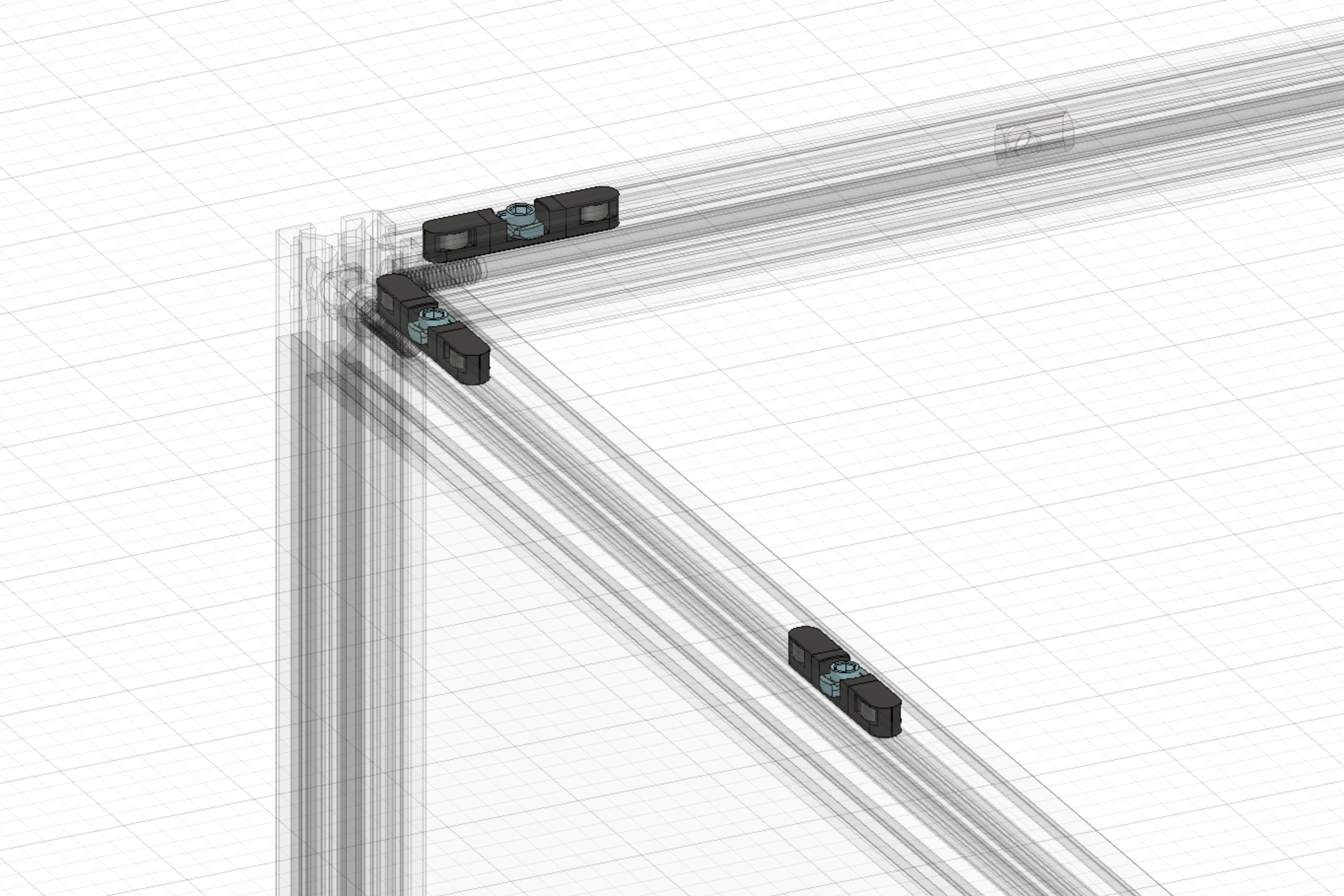

The frame magnet inserts are designed to (1) require only printed parts and no additional fasteners aside from the 6x3 magnets, (2) sit inside the frame slot flush against the aluminum frame face, (3) be easily adjustable, and (4) retain the magnets without glue and allow removal for correcting polarity or salvaging. Discord@PF VT.520 came up with the idea of using a hammerhead-style rotating nut to tighten and press against the magnet insert, holding it in place. There are two included versions of the inserts. Magnet-Insert.stl is the original design but may be slightly more difficult to print due to the bridging involved. Magnet-Insert-Side.stl is redesigned for easier printing; namely, reoriented on its side, uses 45° chamfers rather than fillets, and does not require bridging.

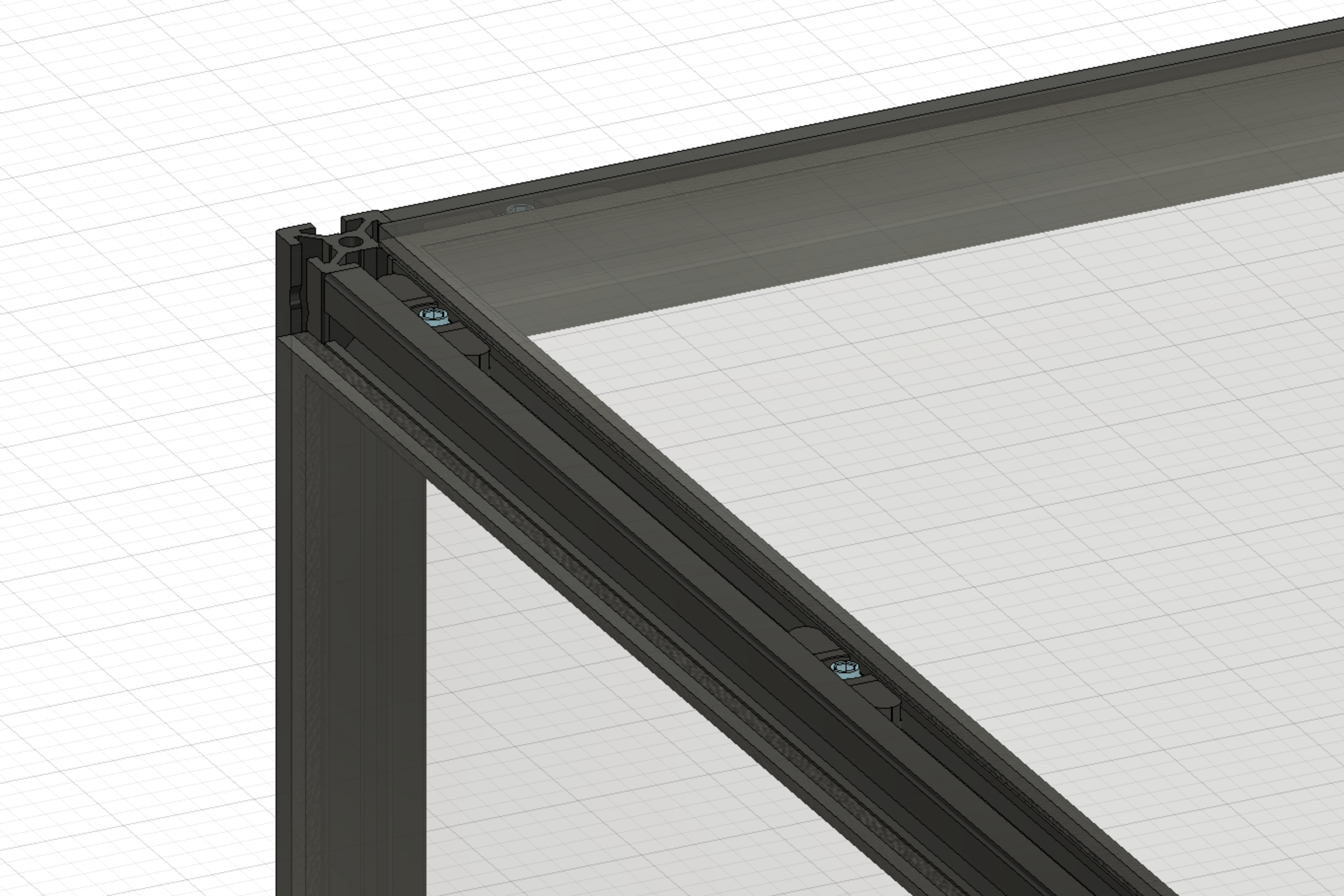

The panel's ability to sit right up to the face of the frame allows the panels to pop on and off without any interference.

The only required parts are a small amount of VHB tape and a lot of magnets (48 6x3mm magnets for each panel).

Magnet inserts hold two 6x3 magnets and is held in the aluminum extrusion with an unhammer

The corner and mid-panel clips hold matching 6x3 magnets

Installation jig makes it easy to set the proper spacing for corner inserts