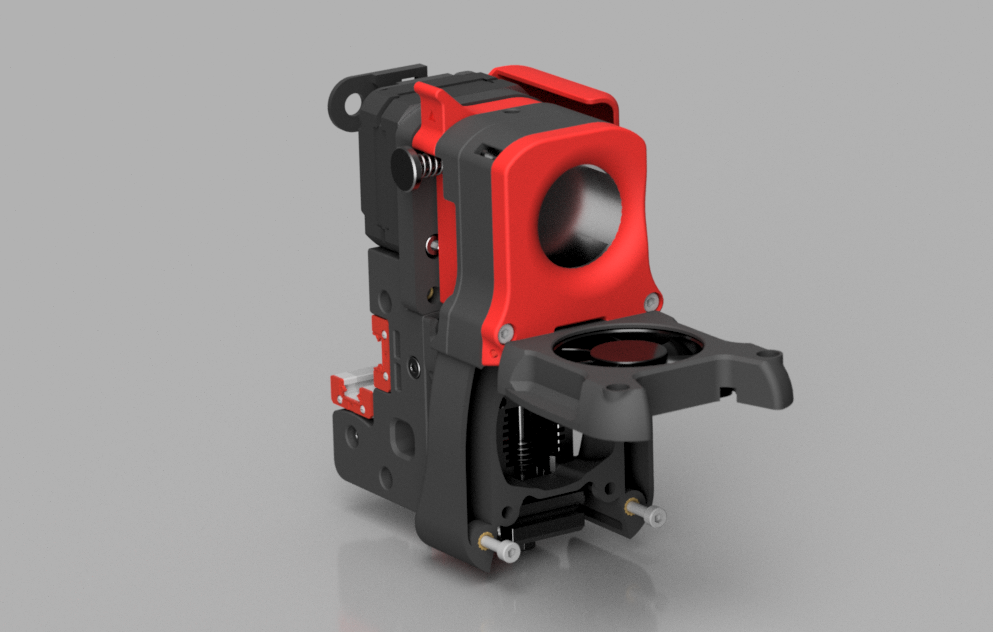

For the Mosquito hotend, this mod shortens the Afterburner tool head by 10mm along Y. It reduces weight at the maximum lever point on the tool head and gives an open duct so you can service the interior in case of a dropped screw or similar.

You will switch to a smaller layer fan for weight and size benefits, at the cost of maximum air throughput. For ABS, ASA, Nylon and other low-fan materials this is often sufficient but you may struggle with PLA.

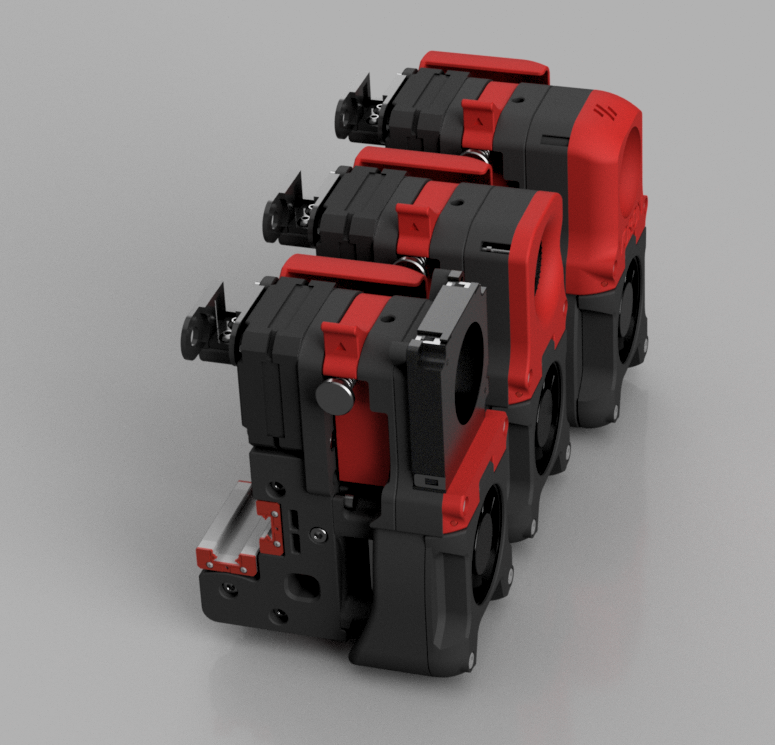

There is an option for a prettier 40x10 (the one from 2.2) and a lighter, more utilitarian 50x10 which is better on all counts except cosmetically.

| File | Note |

|---|---|

| blower_case.stl | |

| blower_lid.stl | |

| duct.stl | You might need supports. I used supporrt from platform only to keep the inside of the duct clean. |

| hotend_fan_cover.stl | You might need supports. I used supports on the duct seal wings to keep them a little nice. |

| v_5010_case.stl | For ugly 50x10 style. Replaces blower_case.stl. |

| v_5010_lid.stl | For ugly 50x10 style. Replaces blower_lid.stl. |