Select a file to view it.

The design of this hinge is based on chrisgonzales already incredible 270 degree hinges. The main goal of this remix was to have the front panels mounted in a way that didn't use any VHB tape or holes that needed to be drilled into the acrylic, and of course, use minimal amounts of additional hardware. After many design iterations and improvements I came to a solution.

If you're going for a super sealed enclosure, then these hinges are not for you. In testing ( at the moment with only 2 hinges per panel ) I found after opening and closing the doors several times, they would slowly lose alignment ( only by fractions of a mm ) and just need a little push to re-align so the panels would close properly and not collide. This means you'll probably have a gap of a couple mm between the panels at the front if you don't want to be driven crazy by them not staying super aligned. A potential fix would be to print 3 hinges for each panel but I am yet to test this although I strongly recommend you do use 3 hinges per panel if you have a printer larger than 250x250 ( what I'm testing them on ).

11.12.21 - Made subtle changes to dimensions to hold panels closer together whilst having them fully seated in the clamps for maximum strength, also changed recommended print settings for stronger face_plate_bottom.stl.

At the moment I have only tested using 3mm thick foam and that works well, you may be able to get away with 4mm foam, but for anything thicker, you'll need to modify part of the hinge to accommodate this.

I am currently using clamps designed by v6cl

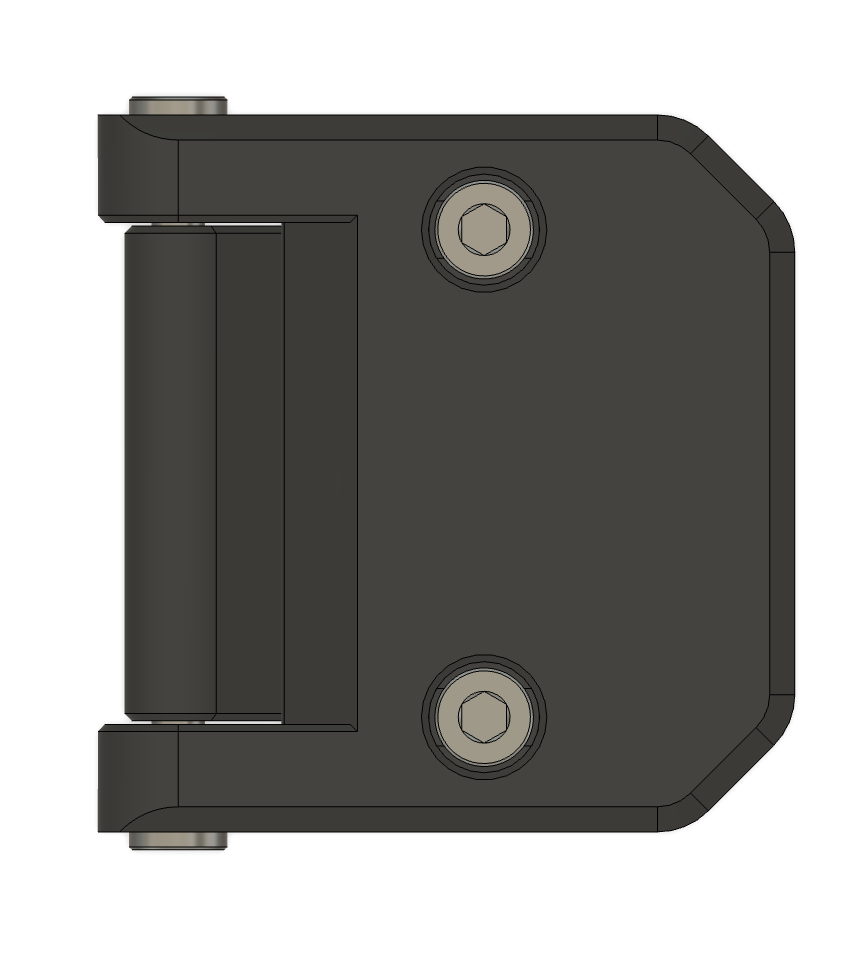

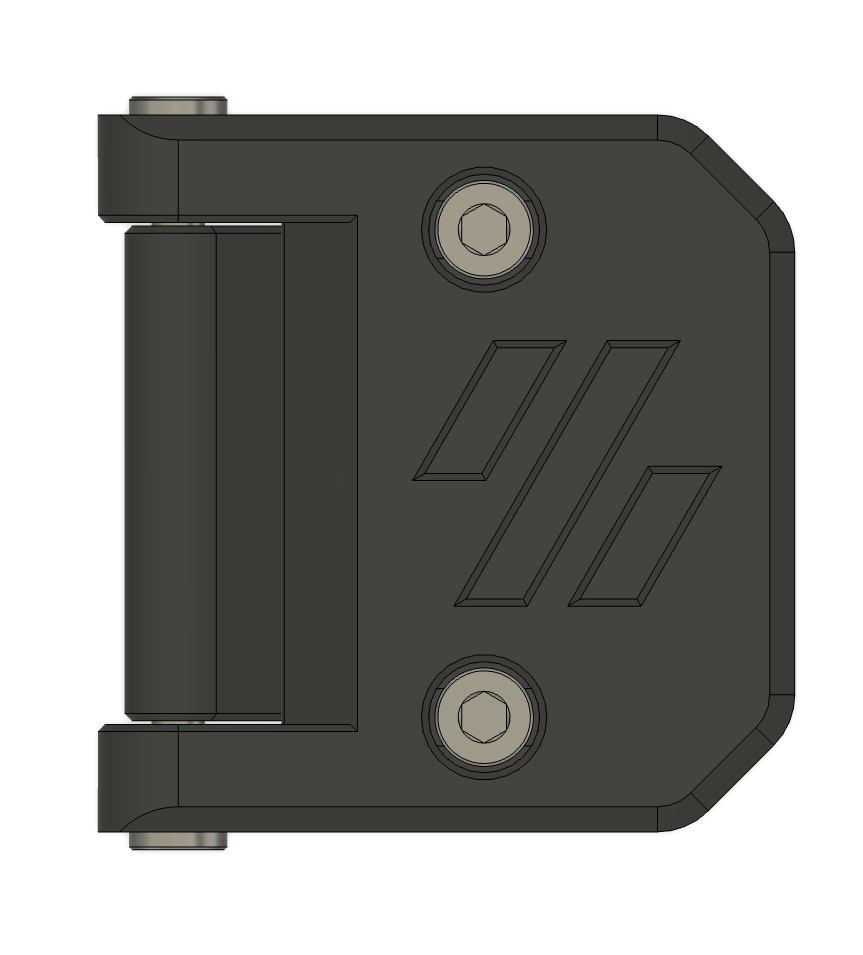

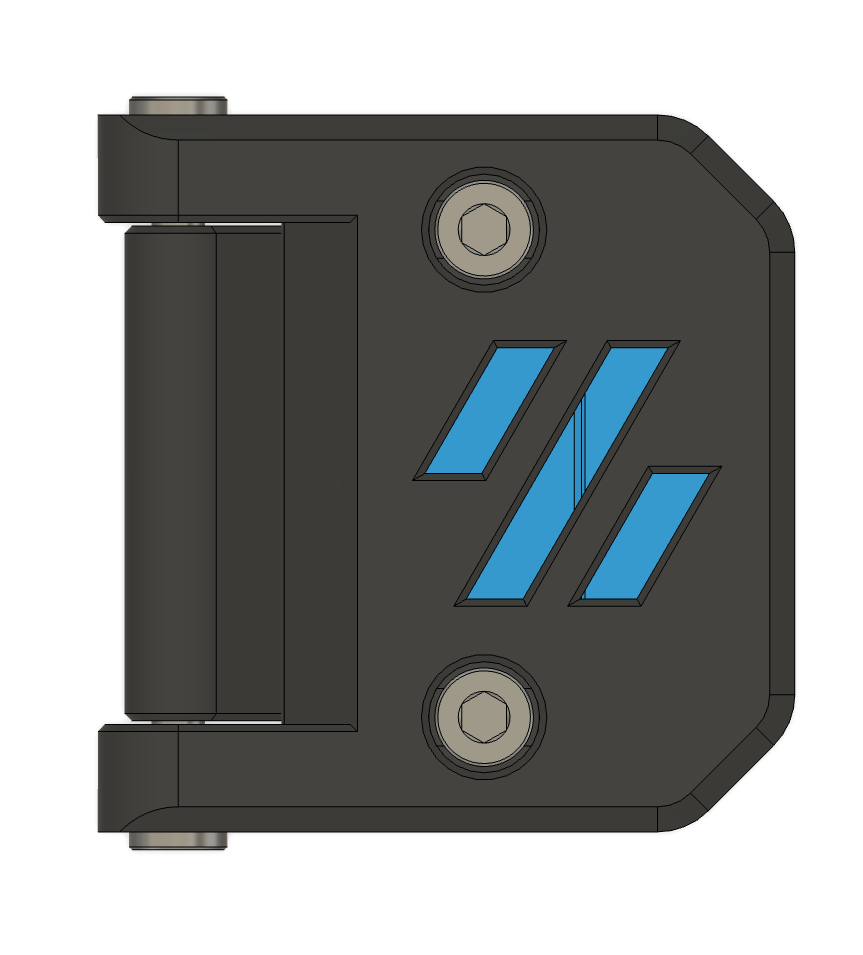

The file names match up with the digrams below.

| Face Plate No Logo | Face Plate Embossed Logo | Face Plate Through Logo |

|---|---|---|

|  |  |

Printed Parts

face_plate_top.stl [x1]

face_plate_bottom.stl [x1]

side_mount.stl [x1]

Additional Hardware

M3 x 8mm SHCS [x5]

M3 Hex Nuts [x2]

M3 T-Nut [x1]

I recommend following the default settings for Voron Parts, and none of the parts require support material.

Layer Height : 0.2 mm

Extrusion Width : 0.4 mm

Infill : 40 % ( 100% For face_plate_bottom.stl )

Perimeters : 4

Solid Top/Bottom : 5

Supports : No

Brim : Optional

Better photos will come in good time ;)

Better photos will come in good time ;)

Better photos will come in good time ;)

Better photos will come in good time ;)