Printable quick release latch for panels on 2020 extrusion

I wouldn't say no to a like and a make on printables if you're that way inclined -

https://www.printables.com/model/172368-voron-24-filament-latch-or-any-2020-extrusion

Intro

This is originally inspired by a youtube video - https://www.youtube.com/watch?v=6p7M18oPn3k

Another user is creating cad and variants - https://github.com/v6cl/My-Voron2.4-Customs/tree/main/Panel_Locker

So why did you do it?

- I wanted a variant with filament hinges

- I found it didn't put quite enough pressure on the panel and my attempts to moodify the cad failed

- Decided the best way to understand it was to design it

- Wanted adjustable "pressure" and thought using a sweep on the latch was a nice solution making the most of the flex of ABS

- Wanted everything as a parameter so I could tune it

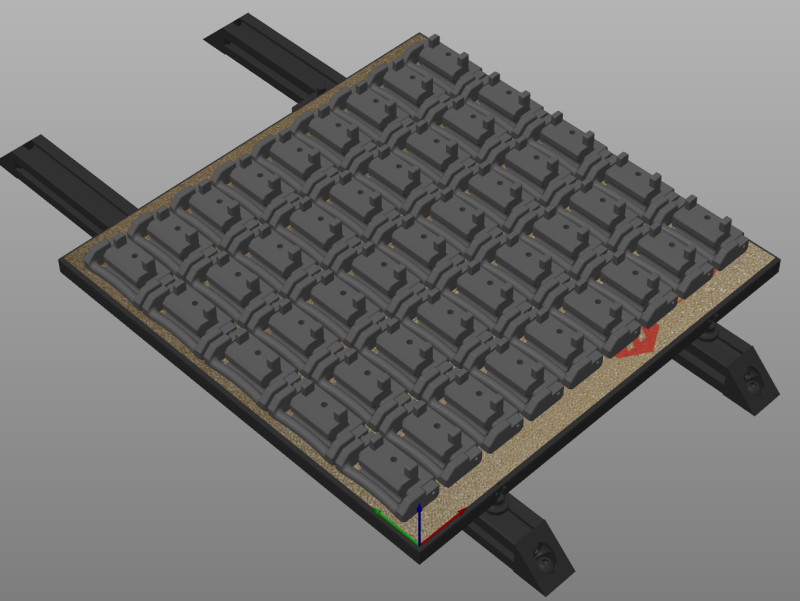

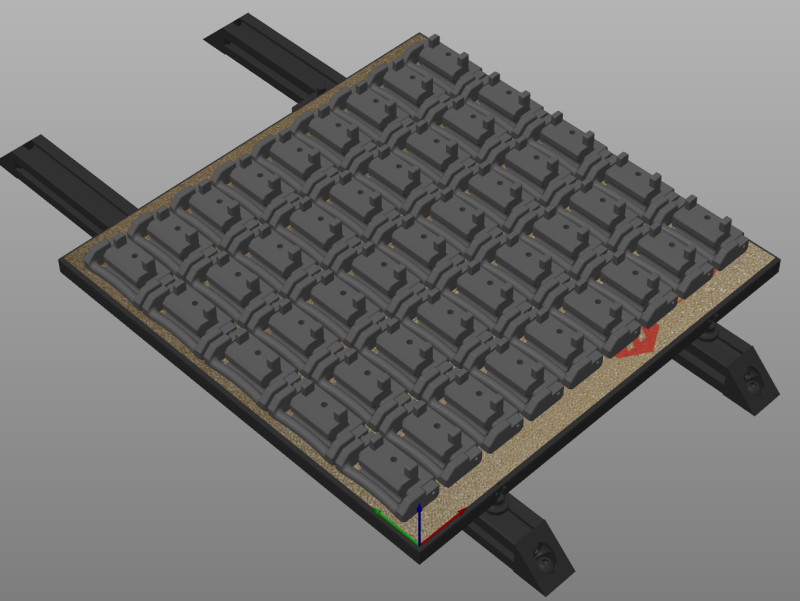

- Build plate density, a bonus of using a filament hinge is that the area used for each hinge is much smaller

45 instances on a 250 buildplate

Hardware

- 3.0mm-5.5mm - m3x12

- 6.0mm-8.0mm - m3x16

- 8.5mm - m2x20

The process

- Cad attempt one failed, just modified surfaces to create a filament variant but adjustement beyond that failed

- Cad attempt two failed, created a traced version copying the dimensions but again couldn't get a reliable adjustment

- Cad attempt three of the cad sketch made as built was finally onto something, took until v45 before I had something that seemed to fulfil my requirements, then after thinking overnight revisited earlier designs and finally hit RC at v68 (18 actually printed)

- Final design and thankfully discovered sheeter which allows me to produce many stls based on parameters

Assembly

- Print parts (do test prints to ensure you're happy with the fit before going wild)

- Assemble to correct orientation

- Insert two short filament lengths connecting middle hinge to hinge body, one from each side

- Insert one long filament length connecting middle hinge to outer hinge

- The filaments are a tight-ish fit on the hinge arms but loose in the pivot intentionally

- Connect to frame using with hammer nut or spring loaded nut with either m3x12 or mx16 depending on size of hinge printed

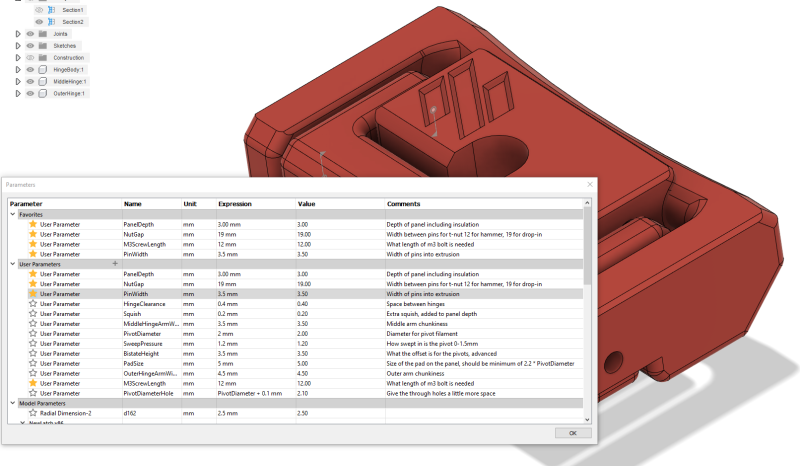

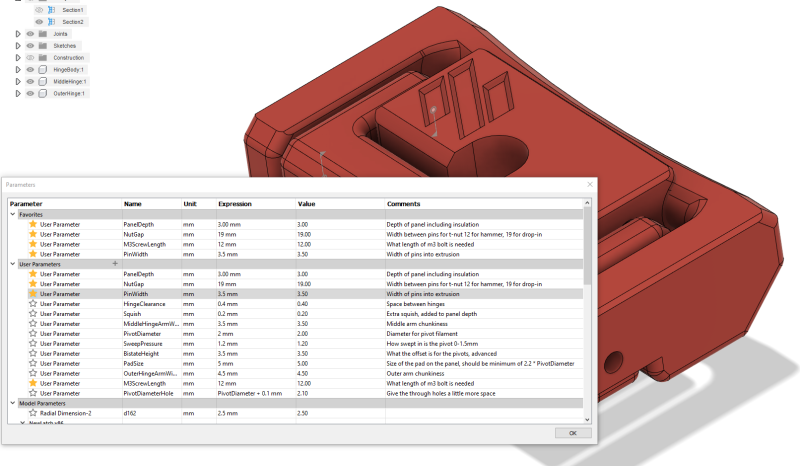

Parameters

To make your own custom hinges you can modify the parameters in the cad - via Modify -> Change Parameters. Removing the logo just requires

you to supress the logo extrusion (last extrusion in the first group).

Changing these parameters to extremes may either not work or require fixups of chamfers and fillets, or even the primary sketch.

Once done, adjust the build plate view (use top view to ensure clearance) and save the file as mesh.

Changes

2022-02-11: Added detent from devincody

2022-07-29: Reworked sketch to resolve in Fusion 360, re-exported fixing some incorrect sizes

discord:whistlinric